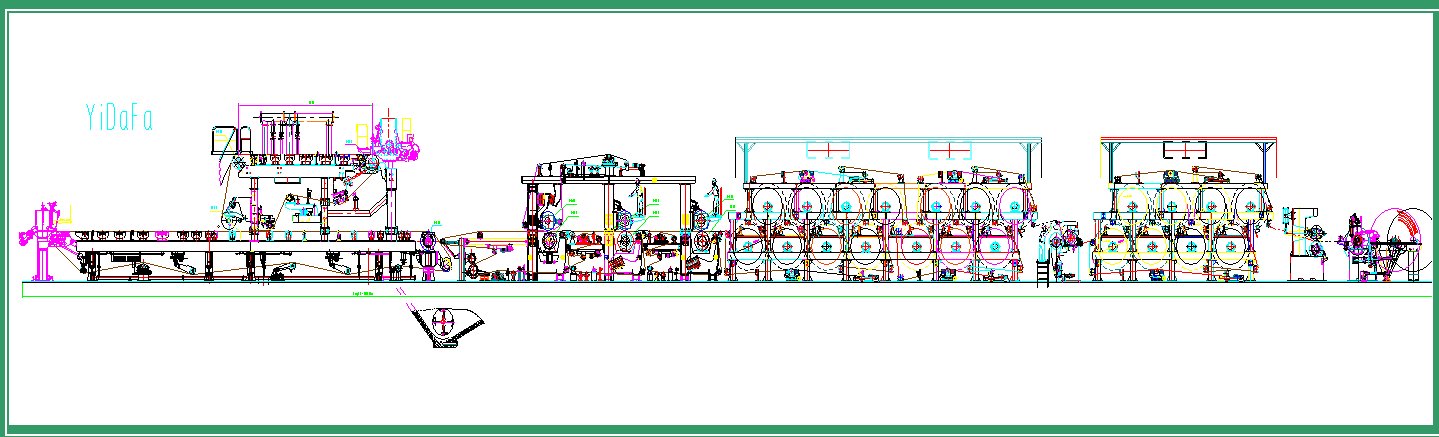

The whole production line from wheat or rice straw to kraft paper rolls.

The whole production line from wheat or rice straw to kraft paper rolls.

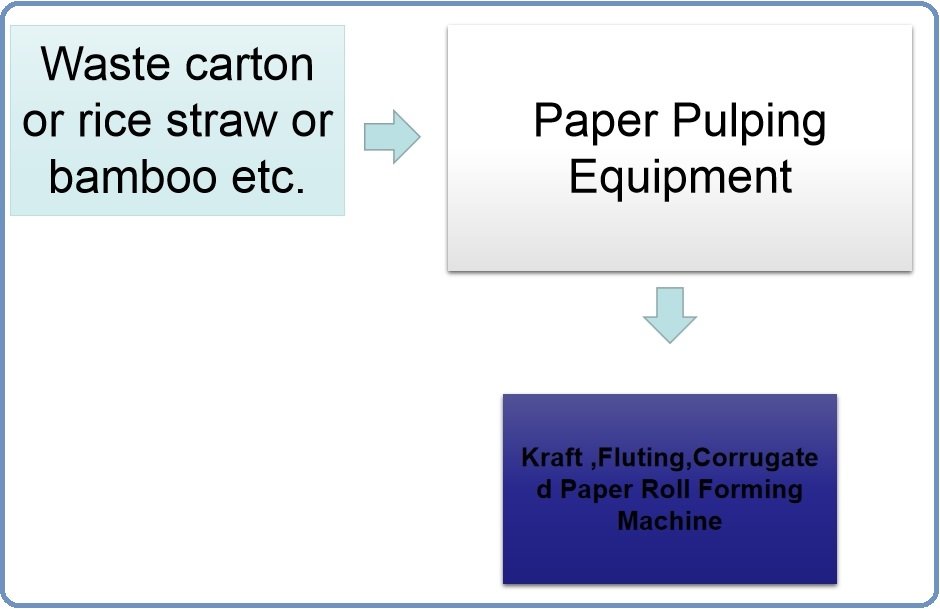

This machine could make kraft paper or corrugated paper rolls from rice straw or wheat straw

Wheat straw or rice straw pulping equipment.100% chemical straw pulp or mixed with recycled waste paper pulp.

Rice Straw is one of the most important materials that has been used for pulp and

paper production due to its abundance and cost-effectiveness. However, the pulping and

papermaking characteristics of the mixture of rice straw and used paper have rarely been

investigated. In this experiment, delignified rice straw was mixed with used paper in order to

make recycle papers with acceptable properties. Soda pulping process was carried out to

remove out of lignin. The delignification was designed to measure the effects in terms of

sodium hydroxide concentration and temperature, on the cellulose and lignin content of rice

straw, and its tensile strength and water absorption. The mass ratio of used paper and rice straw

was varied and its physical properties was observed and compared to paper from natural rice

straw. The delignification was conducted using NaOH concentrations (4-10% w/w) and

temperatures (60-90 degree) for 1 hour. The ratio of rice straw to used paper was varied (1:1-1:9).

An optimum condition was obtained from rice straw delignification at NaOH concentration of

8% and temperature of 90°C. The results of the optimum condition obtained the highest

amount of cellulose content and tensile strength while having the lowest amount of lignin

content and water absorption

3. Kraft paper roll forming machine.

Paper machine technical description: | |

1. main products: | Container board, kraft paper |

2. Quantitative: | 100 ~ 200 g/㎡ |

3. Equipment form | Stacked mesh multi-cylinder |

4. Yield: | 50T / 24h |

5. Clean paper width: | 2400-2500mm _ |

6. Design Speed: | 200 m/min |

7. Working speed: | 70-170 m/min |

8. Roll balance: | Grade G2.5 |

9. Dryer Balance: | G level 4 |

10. Roller: | G 1.6 |

11. transfer method: | AC motor and digital display division frequency conversion speed regulation drive |

12. Arrangement: | Left and right mobile phones (selected by the user) |

13. gauge: | 34 00mm |

1 4. Large item name 1 | Dryer: Ø 150 0mm × 22 |

1 5. Bulk name 2 | Stacked net : the length of the lower net is 18000mm , and the length of the net is 6500mm |

If you have any needs , please fill out the form below and we will contact you as soon as possible.