TURNKEY PROJECT:TOILET PAPER PRODUCTION LINE

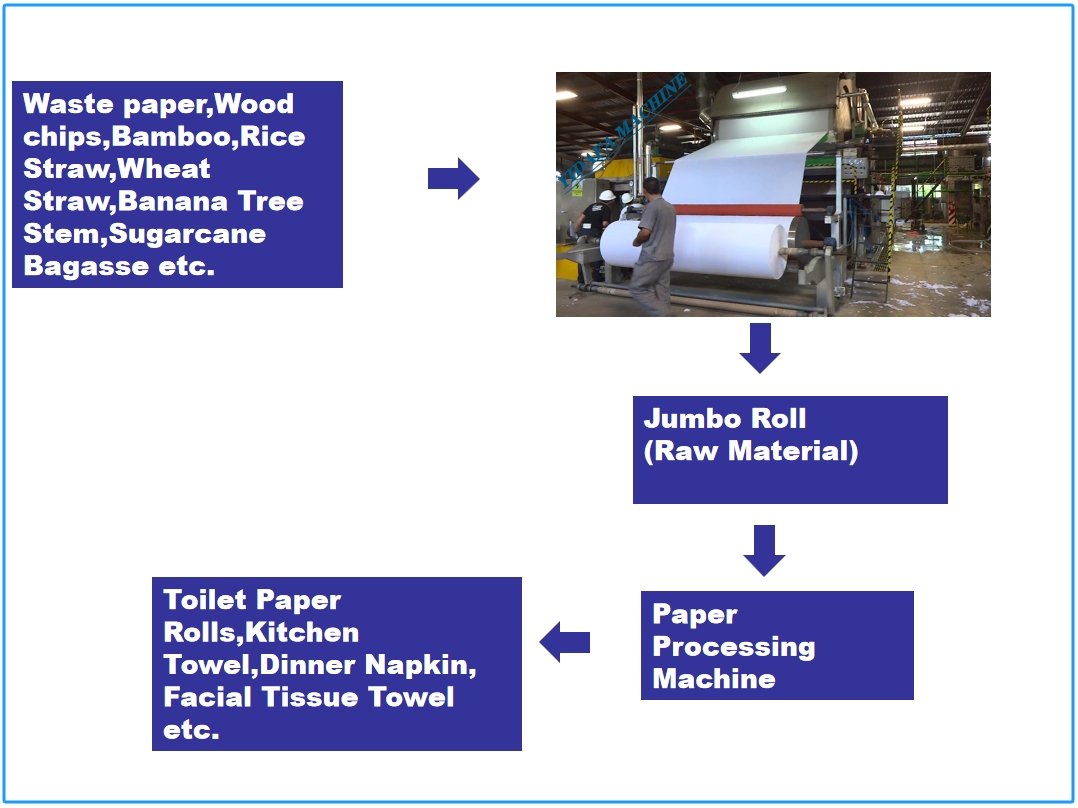

Toilet paper production line is a complex machinery system used to produce rolls of toilet paper from raw materials such as paper pulp. The process involves several stages, including pulping, sheet formation, drying, winding, and packaging.

Here's a brief overview of the main components of a toilet paper production line:

1. Pulping System: The pulping system is responsible for transforming raw wood chips or other cellulosic materials into a pulp. This is typically done in a pulper, where the chips are combined with water and mechanical equipment to break down the cellulose fibers.

2. Refining System: The refined pulp is sent to the refining system, where rolls of felt or screening material are used to further break down the fibers and create a uniform texture. The refining process also removes any remaining impurities.

3. Sheet Formation: The refined pulp is transported to the sheet formation area, where it is formed into a continuous web through a process known as wet pressing. This involves passing the pulp through a series of metal wires or felts, which squeeze out excess water and form a thin sheet of paper.

4. Drying: The wet sheet is then dried using large dryers, which can be either hot air or steam-heated. The drying process reduces the moisture content of the paper from around 80% to 3-5%.

5. winding: After drying, the paper sheet is wound onto a large, rotating cylinder or rollers. The wound paper is then sent to the winding station, where it is cut and stacked into rolls of the desired width and length.

6. Embossing: Some toilet paper production lines include an embossing station, where patterns are pressed into the paper to create a raised texture. This is done using engraved rollers that press the pattern onto the wet paper as it passes through the station.

7. Printing and Packaging: The finished rolls of toilet paper are sent to the printing and packaging station, where they are printed with logos, labels, and other information. The rolls are then individually wrapped in plastic film or shrink wrap to protect them from moisture and contamination.

8. Quality Control: Throughout the production process, quality control inspectors monitor the production parameters and inspect the finished product to ensure compliance with industry standards and customer specifications.

Toilet paper production lines are typically large and expensive investments, requiring significant capital and expertise to operate and maintain. They are found in paper mills and manufacturing facilities dedicated to the production of toilet paper and other paper products.